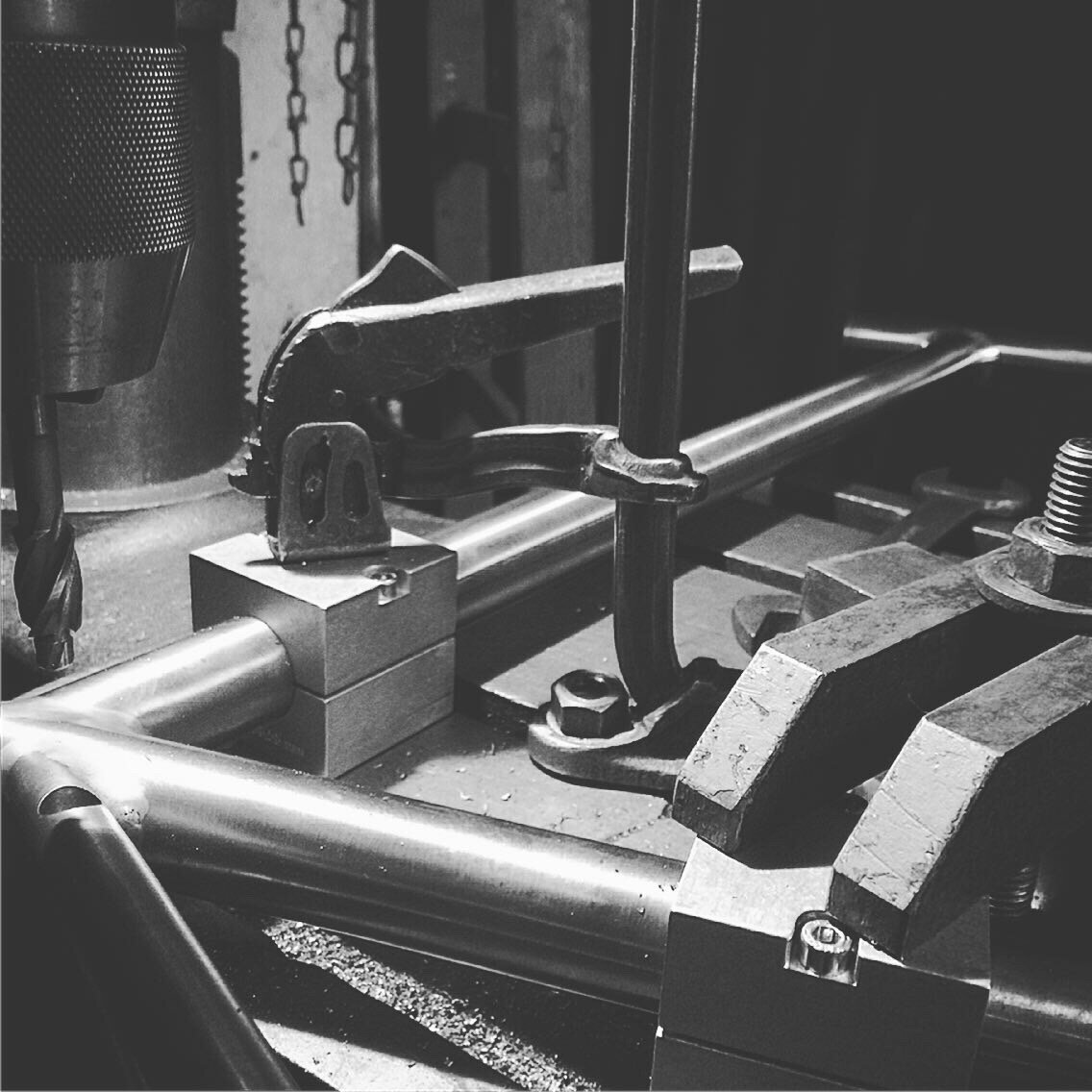

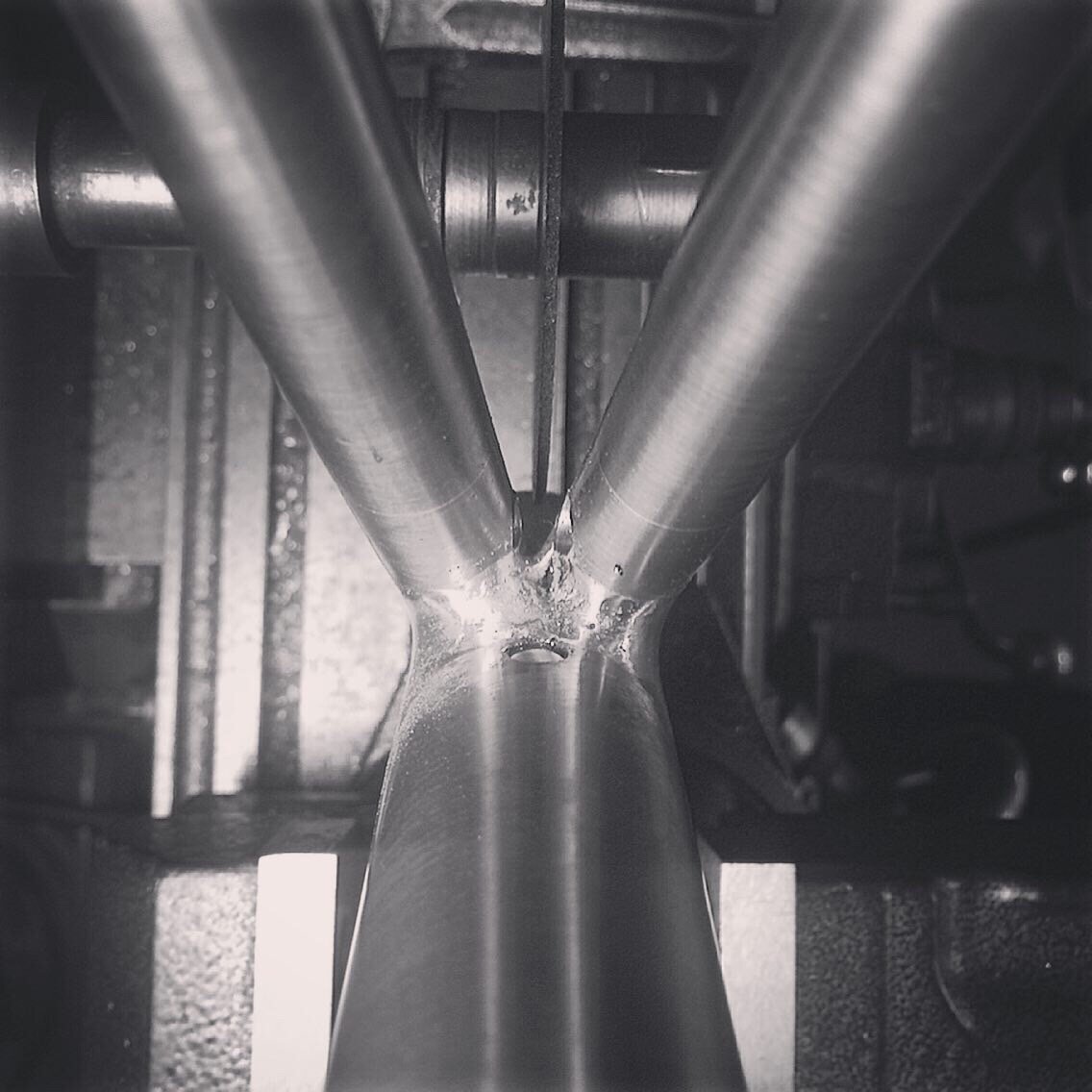

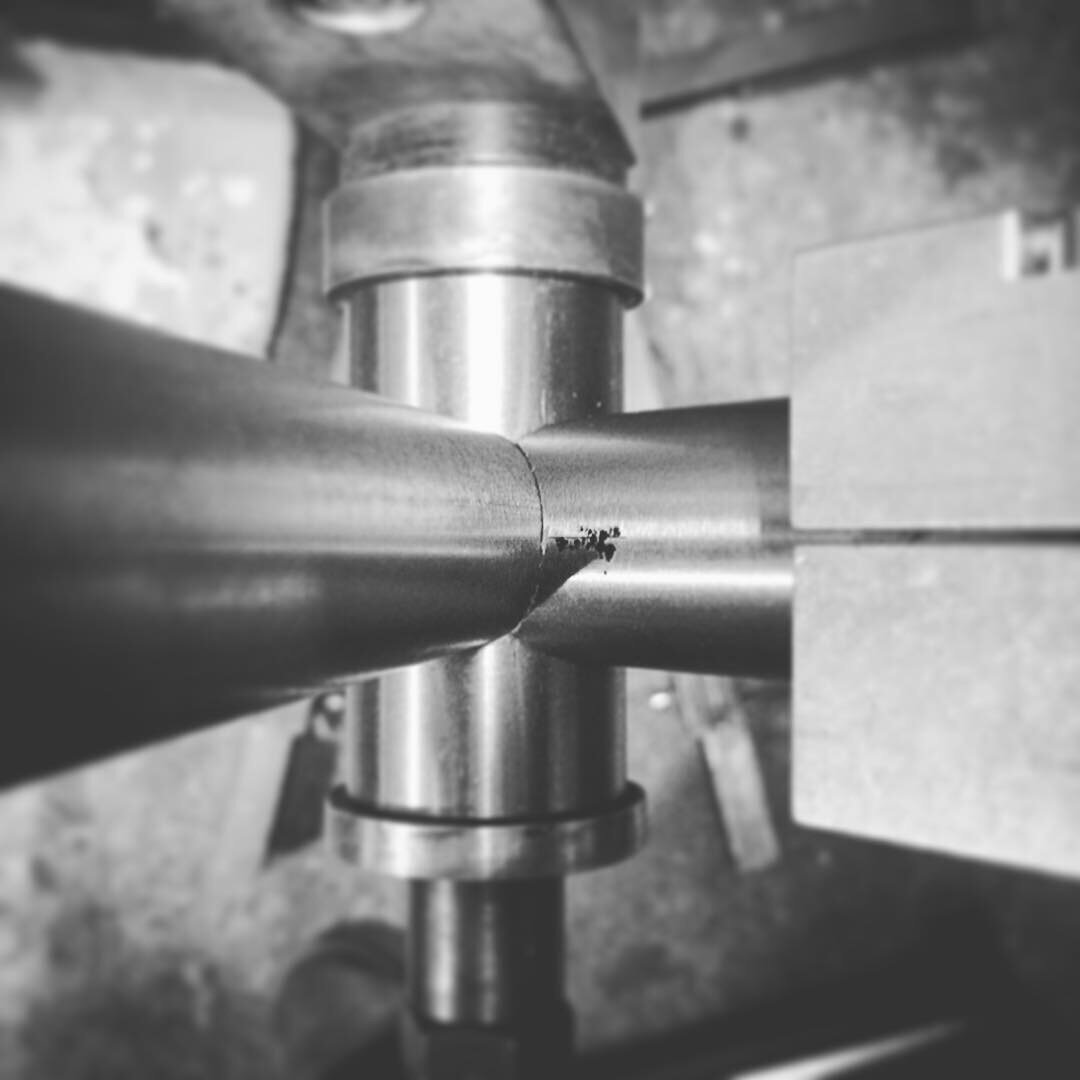

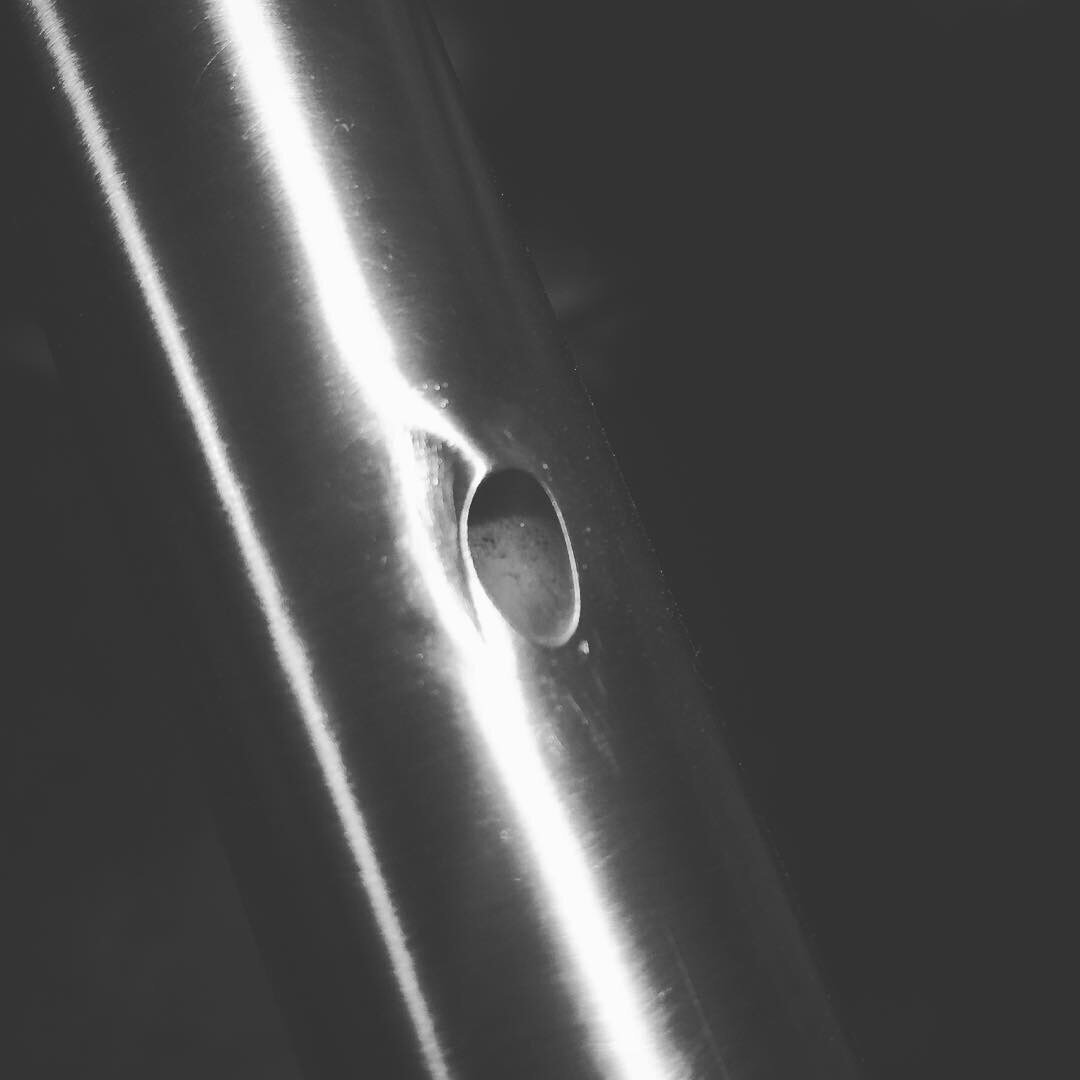

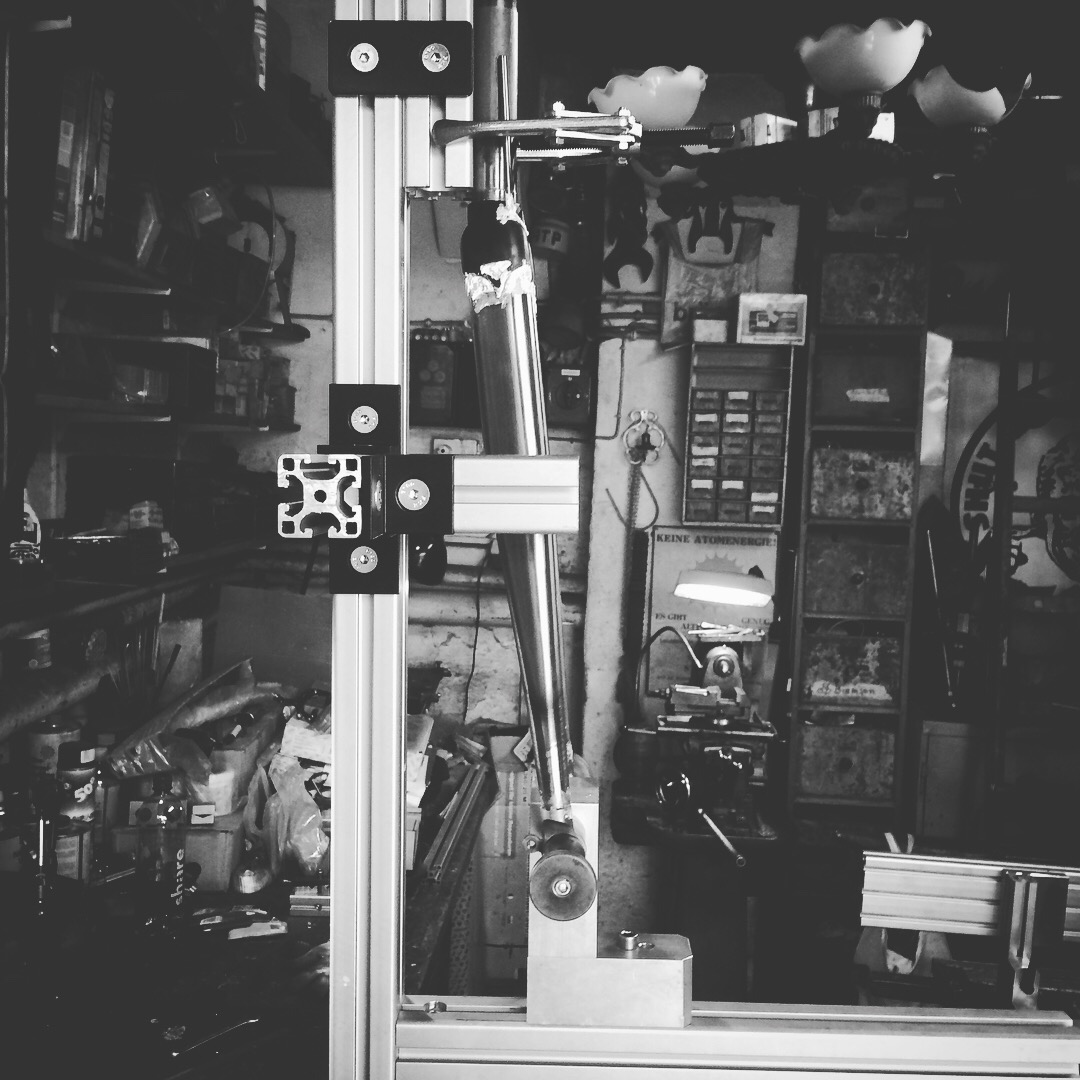

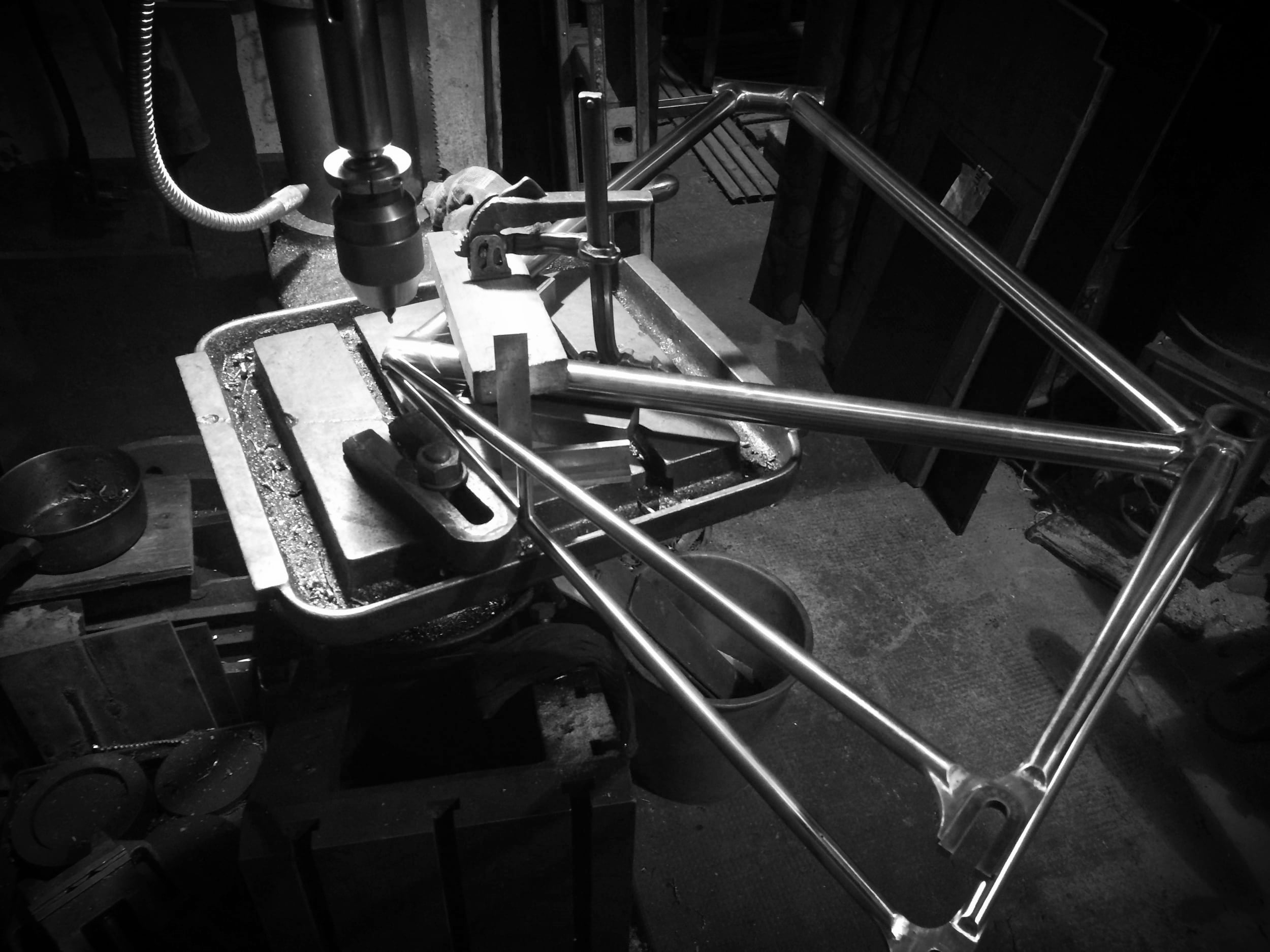

Below you can follow every design in its development to get a glimpse of the manufacturing in the shop. Witness the process of building the rides up from the tubes.

AND FOR MORE VISIT US ON

And get more from our design process and their stories behind.

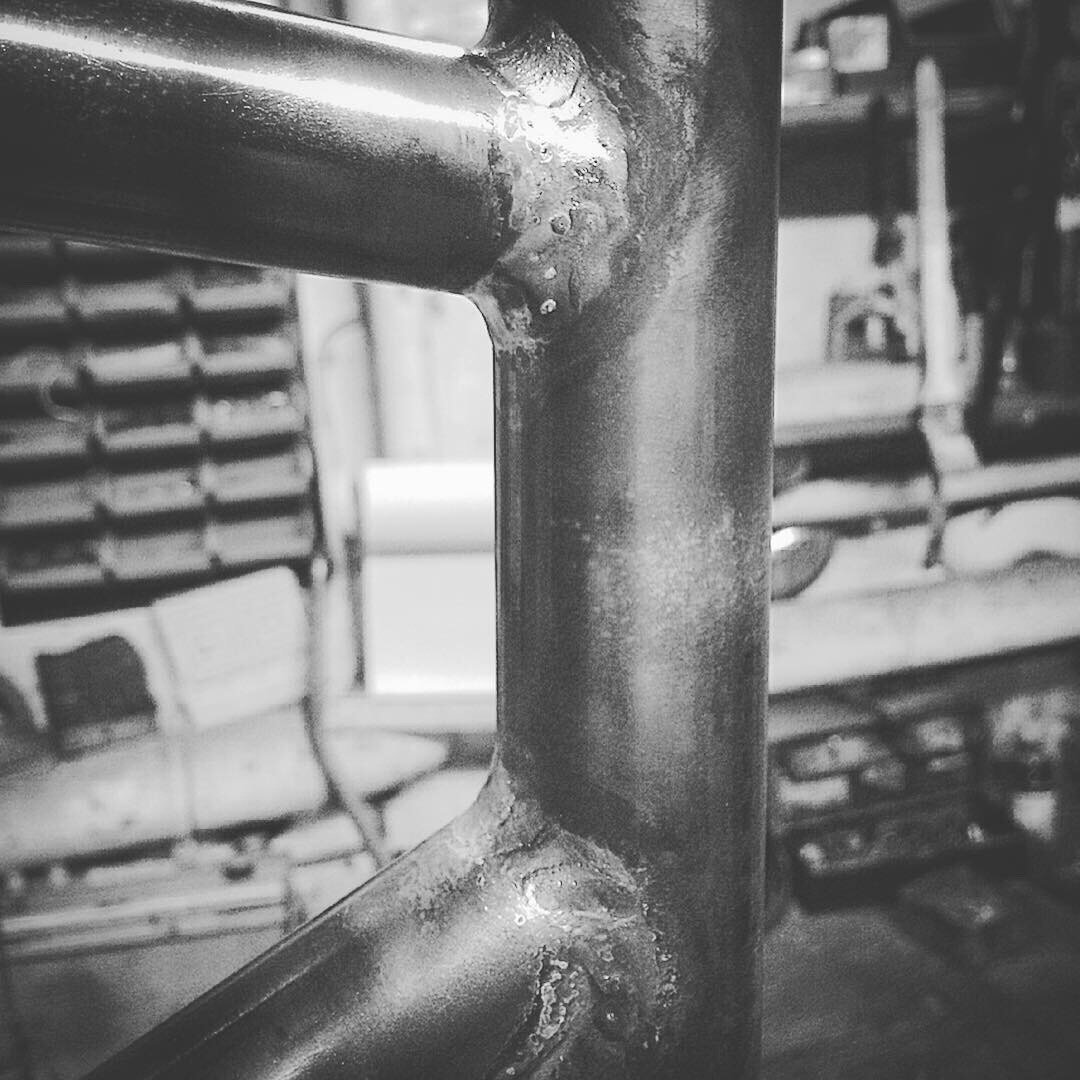

The YAAD CYCLES RD is designed for a rider over 2m tall . So the Geometry had to be developed in a way to stay in an visual balance and not stretch the triangles too much out. We tried to achieved this with a negative sloped top tube and an extended head tube to reduce the use of spacers. The rear triangle is designed with S-bended stays.

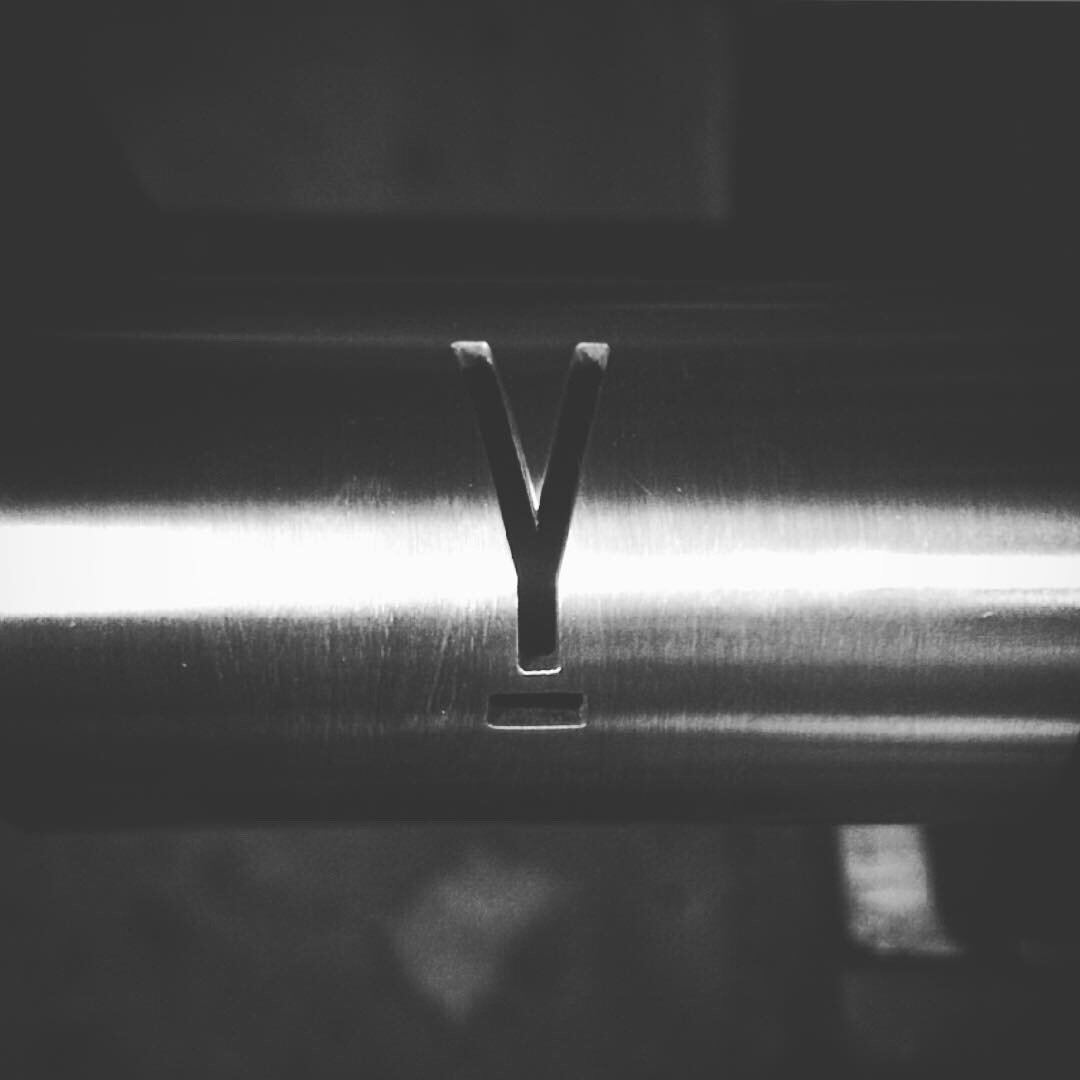

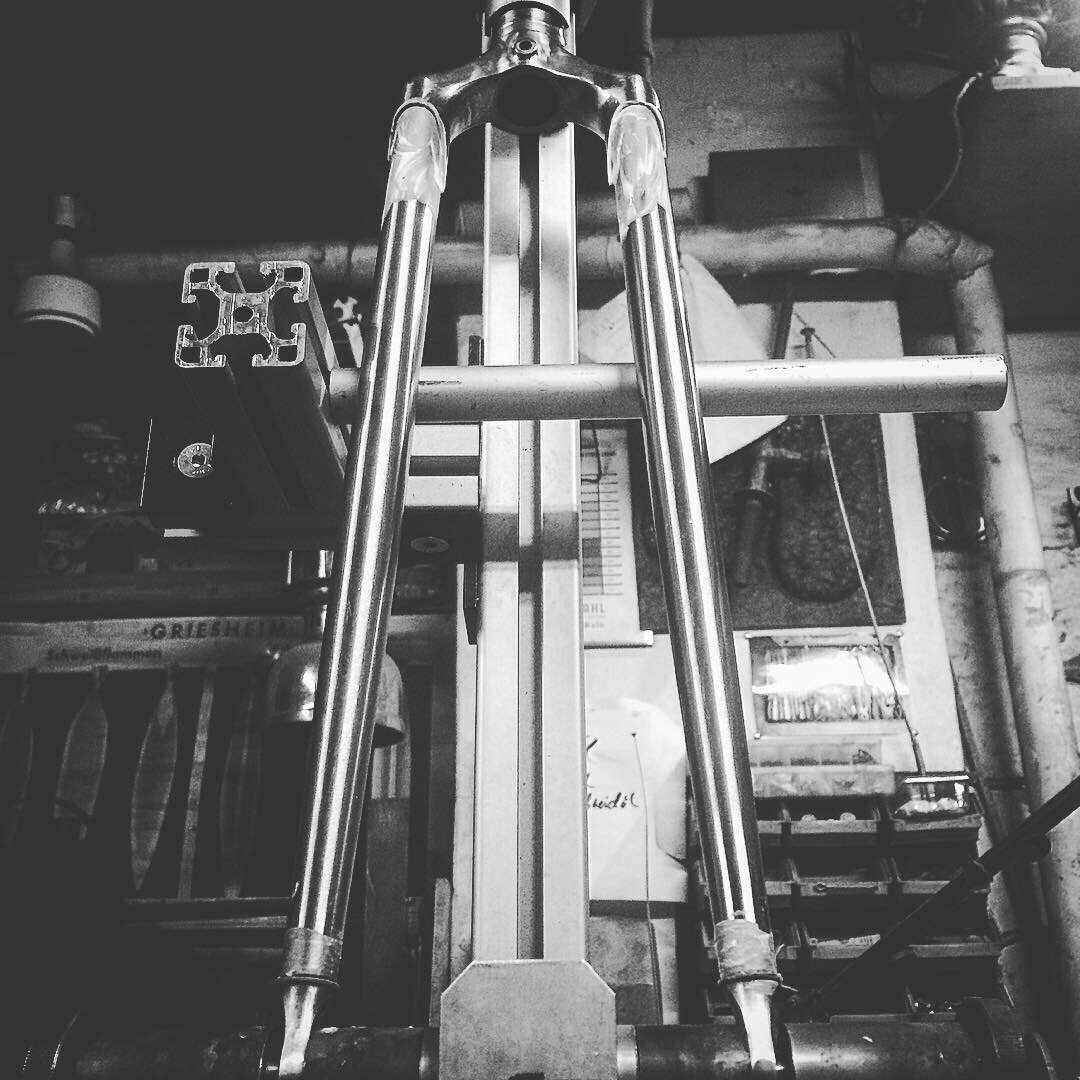

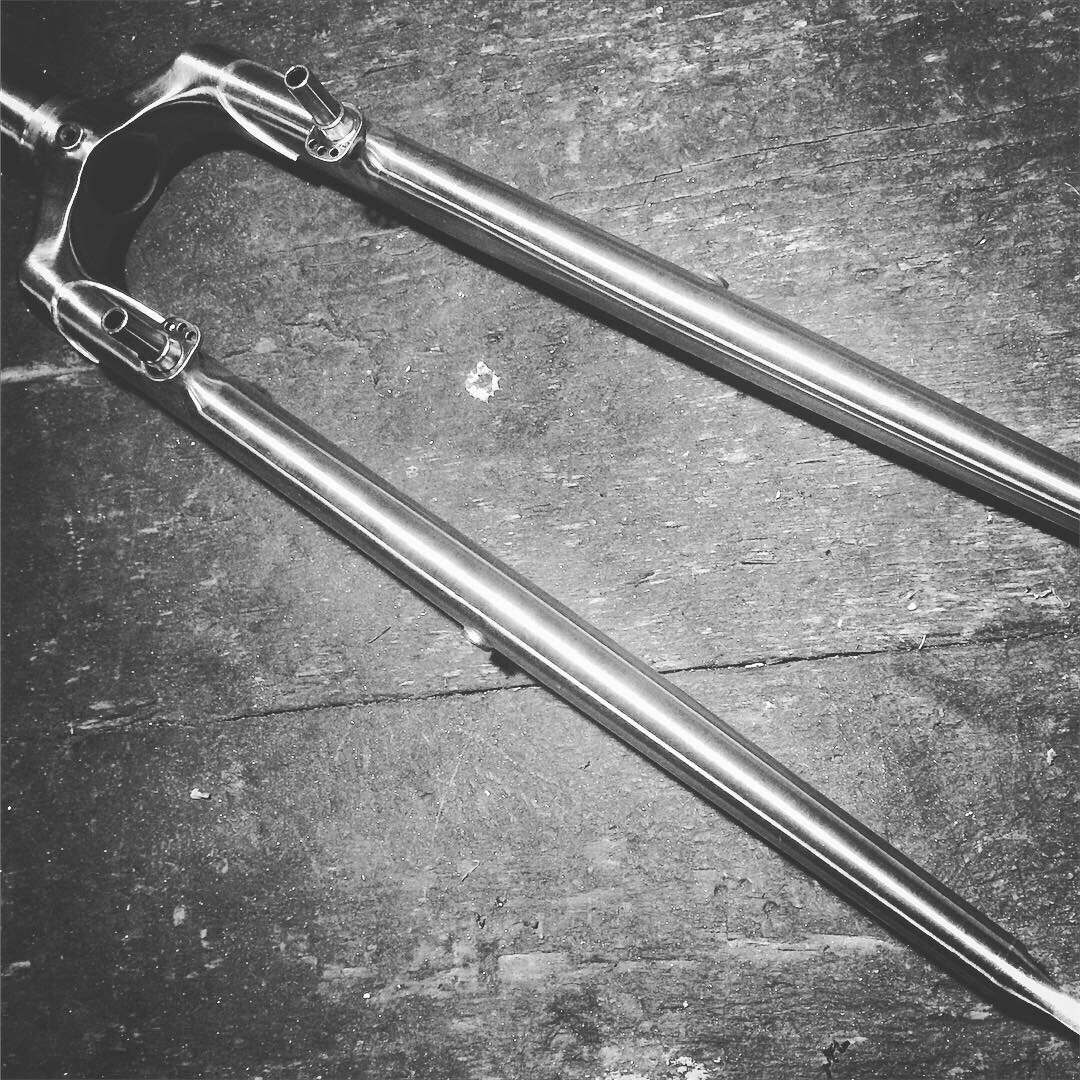

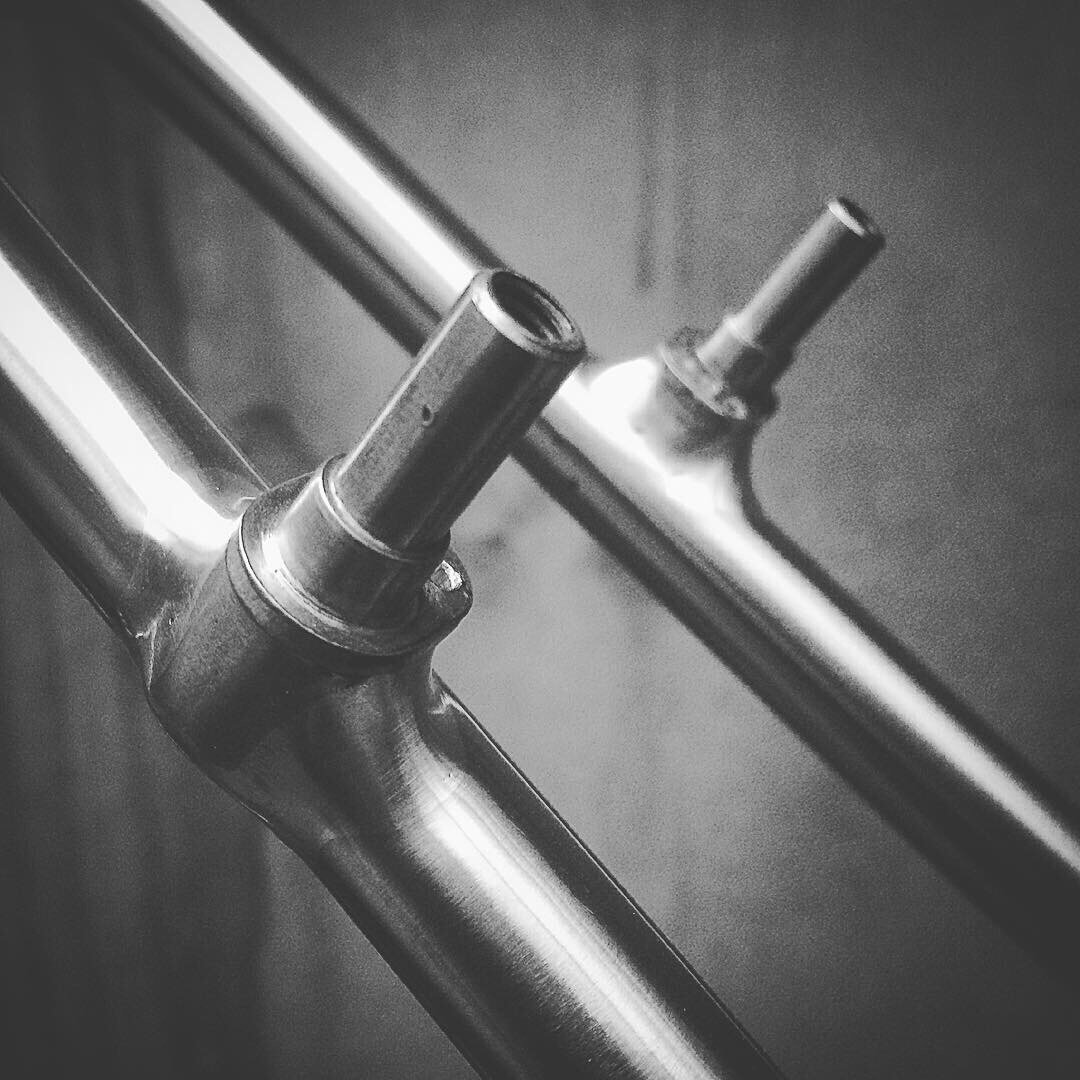

Developed with the fillet brazed technique, it supports internal cable routing for brakes and derailleurs. Unique logo detailing is integrated in the bottom bracket and the front dropouts. Also a Columbus MAX fork with internal lugged fork crown gives this machine the needed front end character.

The YAAD CYCLES FX is designed in the intention to combine the cyclocross geometry with some retro 90’s MTB flair and this as Fixie. Developed with the fillet brazed technique, it supports internal cable routing for V-brakes.

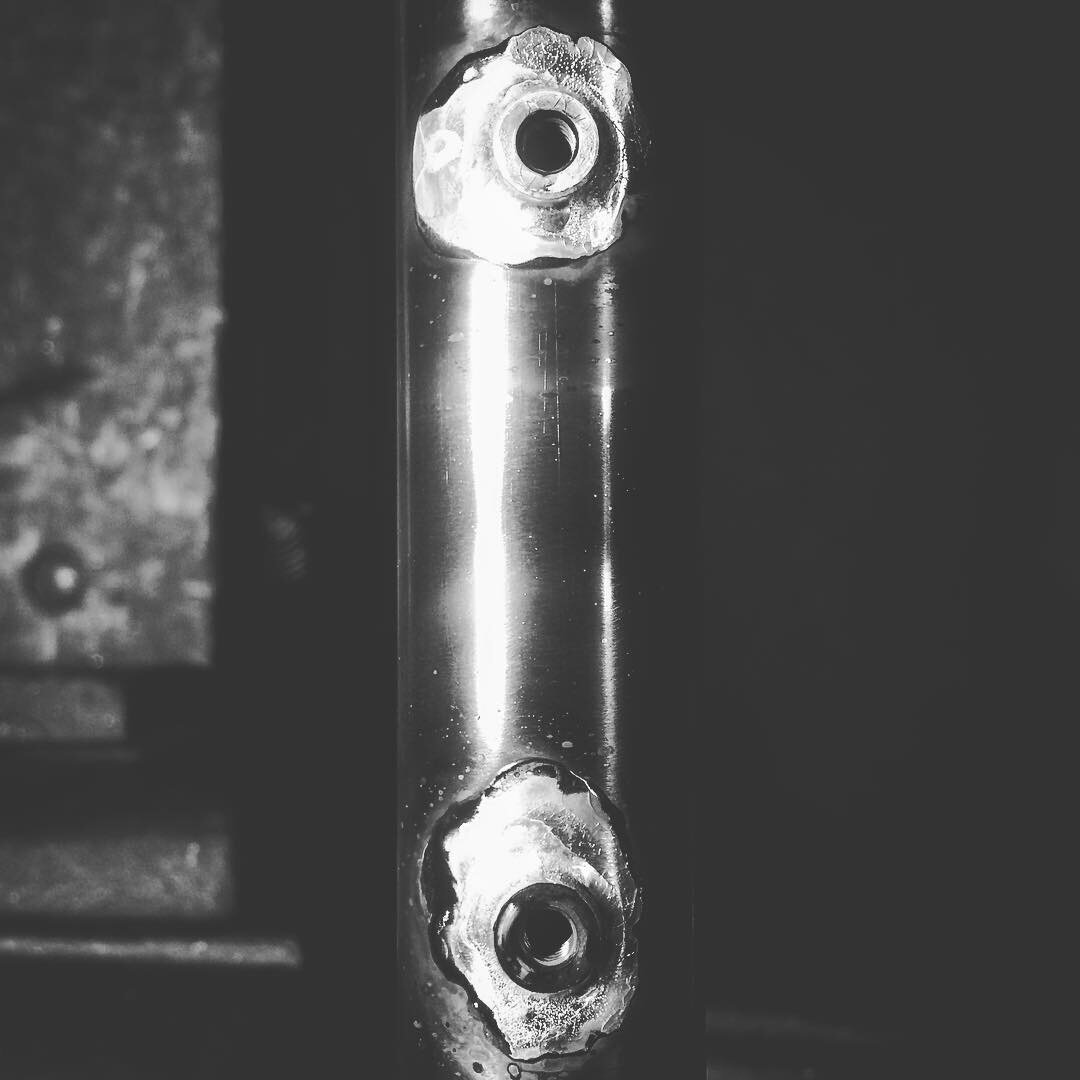

Unique logo detailing in the bottom bracket is integrated and brake bosses for the V-Brakes are brazed on.

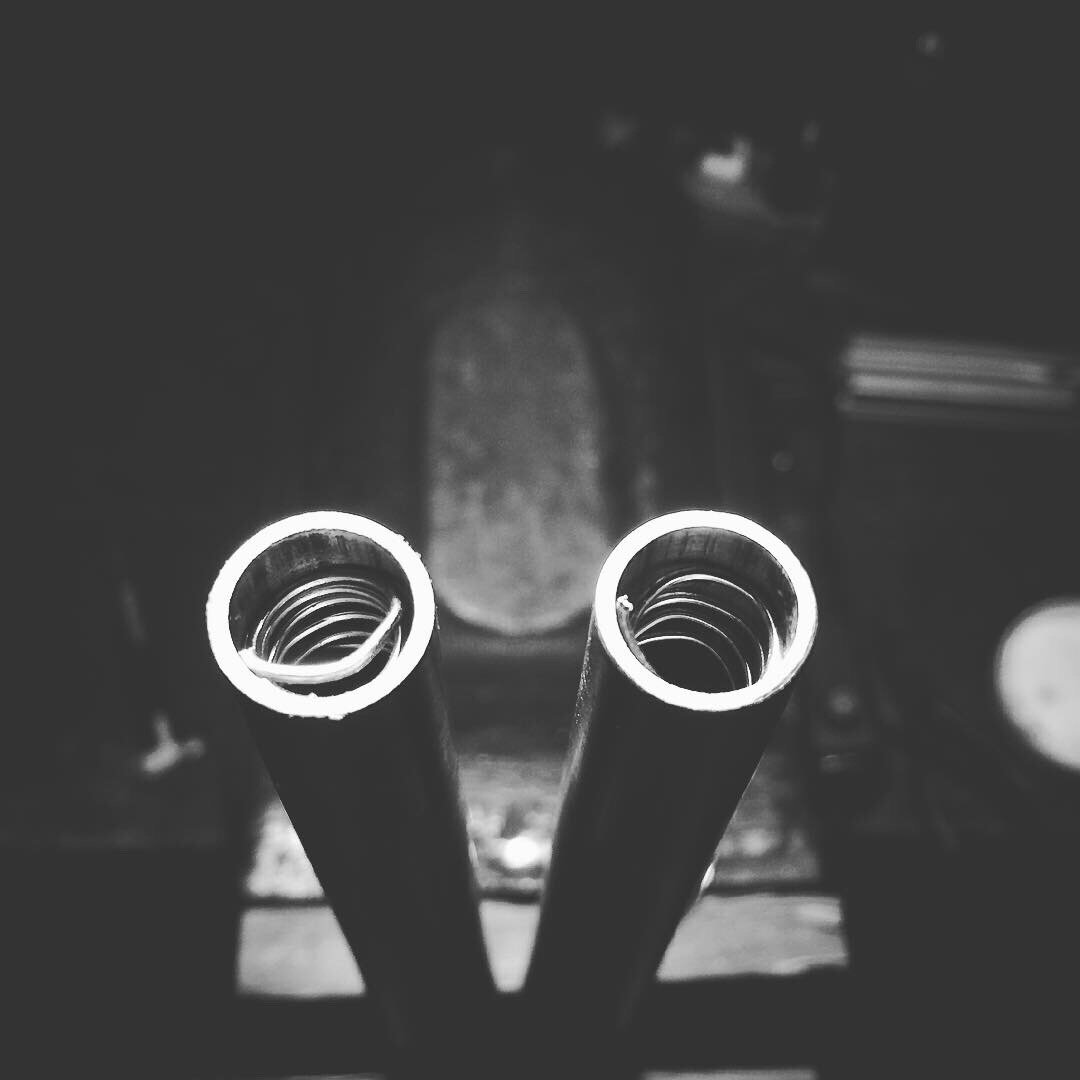

A custom designed minimalistic rear rack needed its individual mounts in seatstays and seattube. The fork is designed with straight Columbus MAX blades and also the dynamo wiring is routed through the blades.

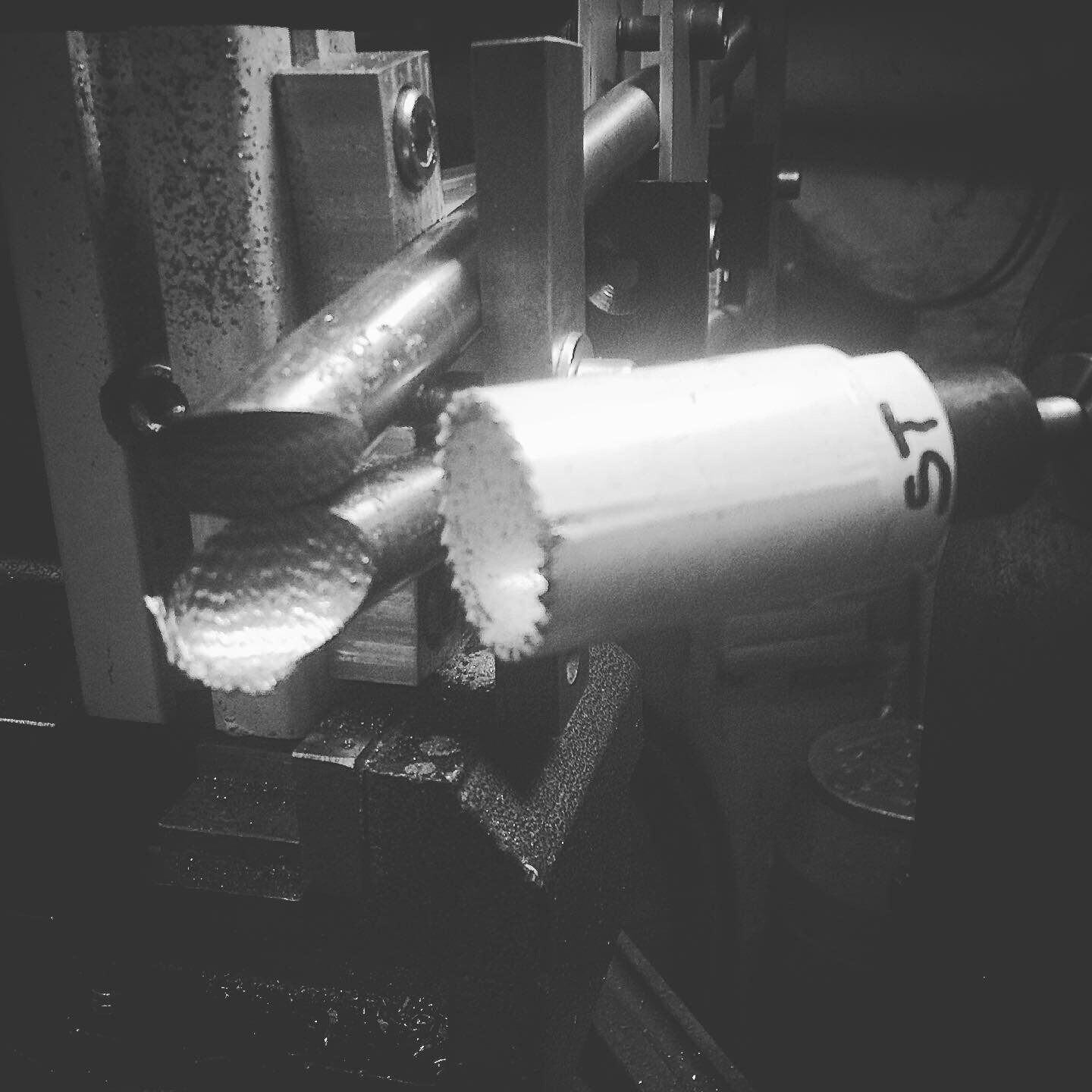

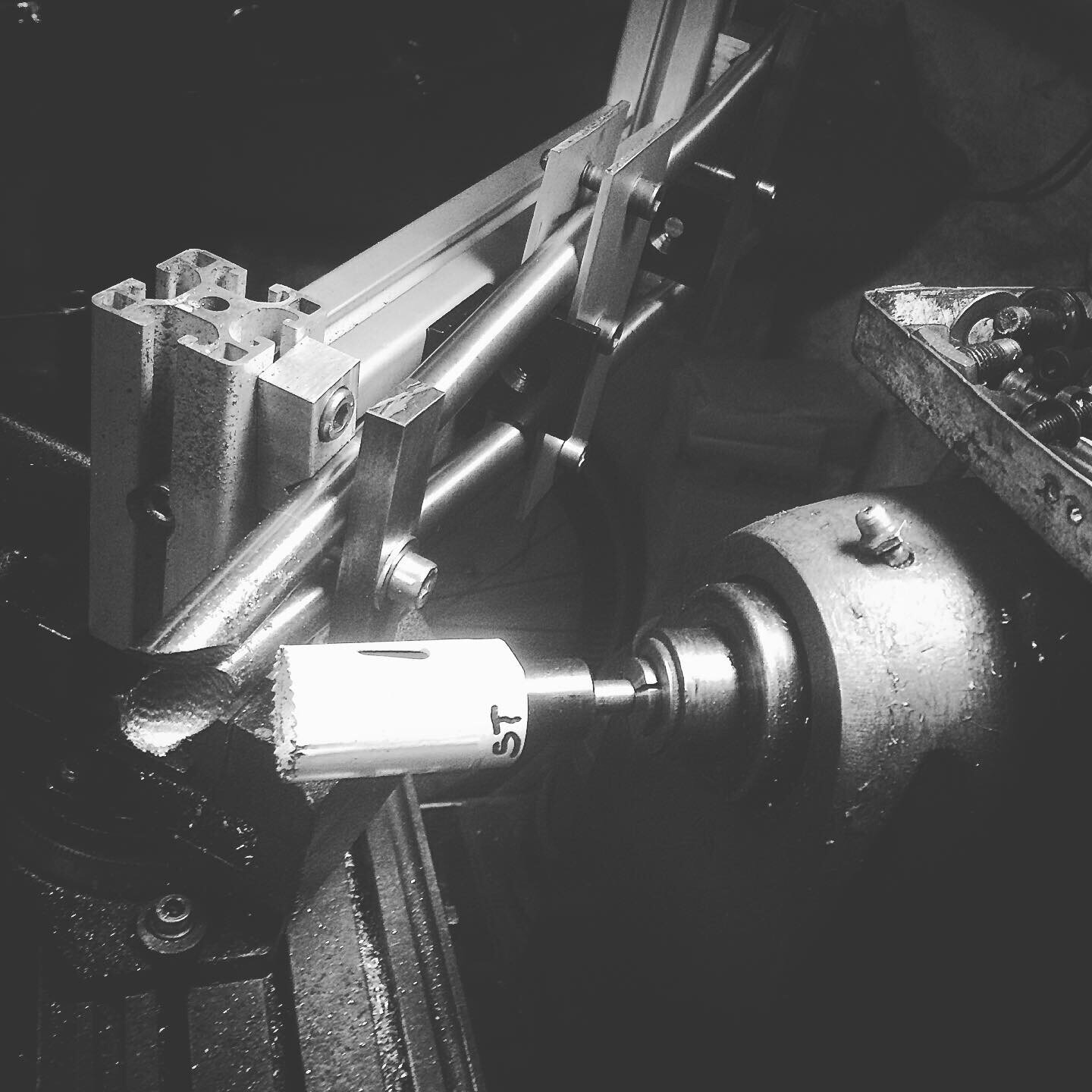

The YAAD CYCLES ST is designed in traditional step through geometry. Developed with the fillet brazed technique, it supports internal cable routing for brakes and as well for dynamo wiring. Unique logo detailing in the bottom bracket is integrated and a chainstay bridge with integrated brake nut is manufactured in house, to locate the rear brake under the chainstays.

The YAAD CYCLE-FB is the first developed frame with the fillet brazed technique, which allows more freedom in the angles of the frame geometry and the tube sections and diameters. A nice clean track-frame-geometry with unique integrated logo detailing.

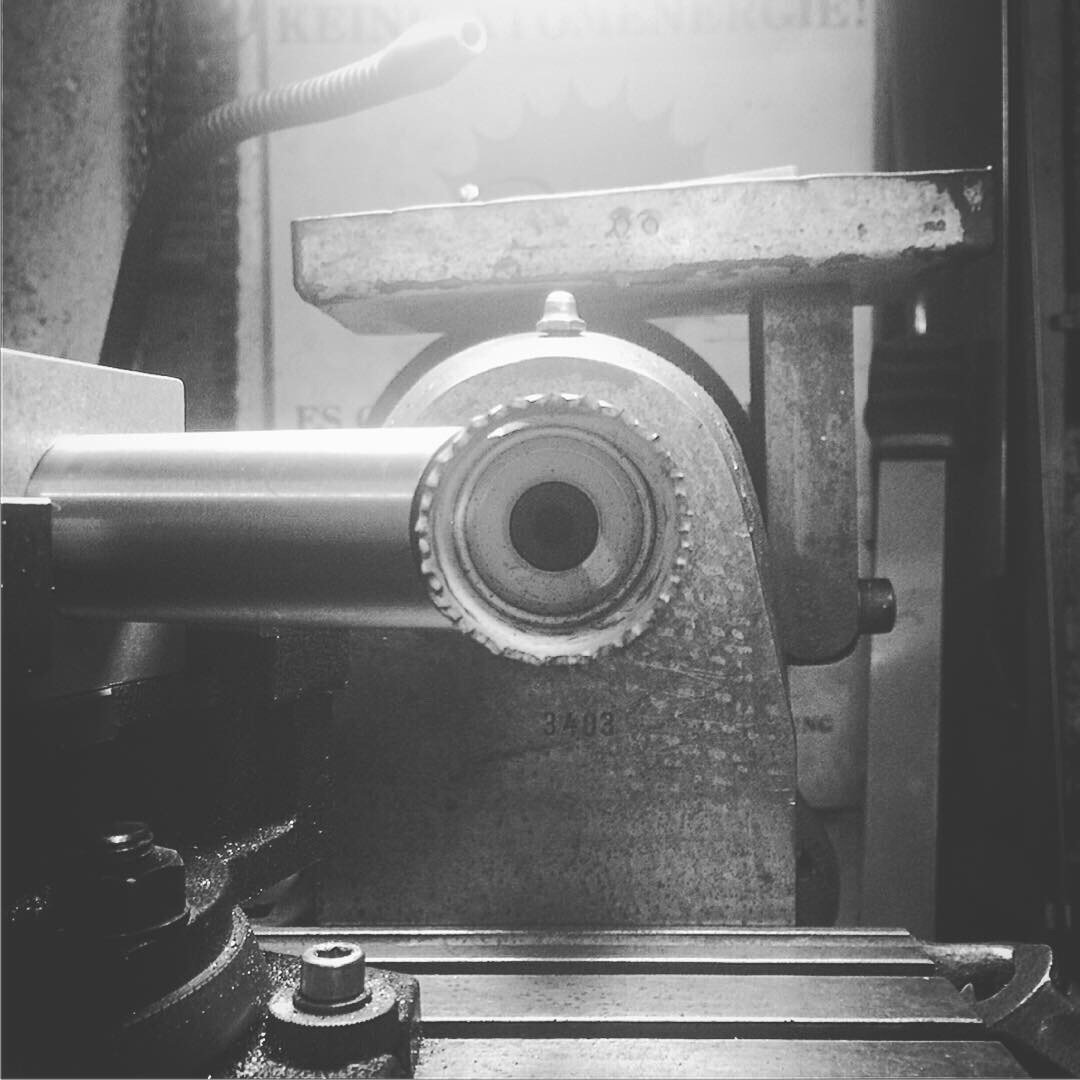

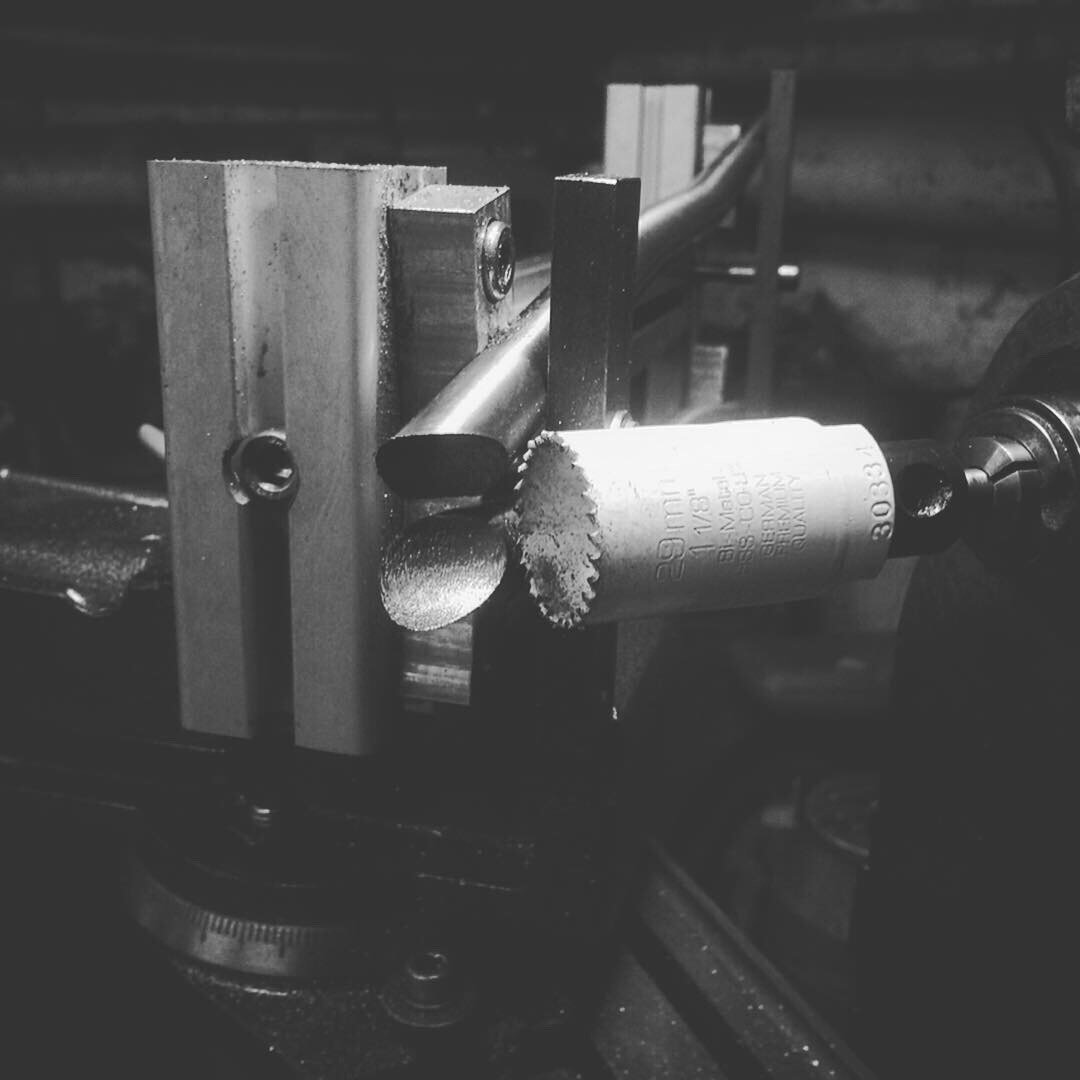

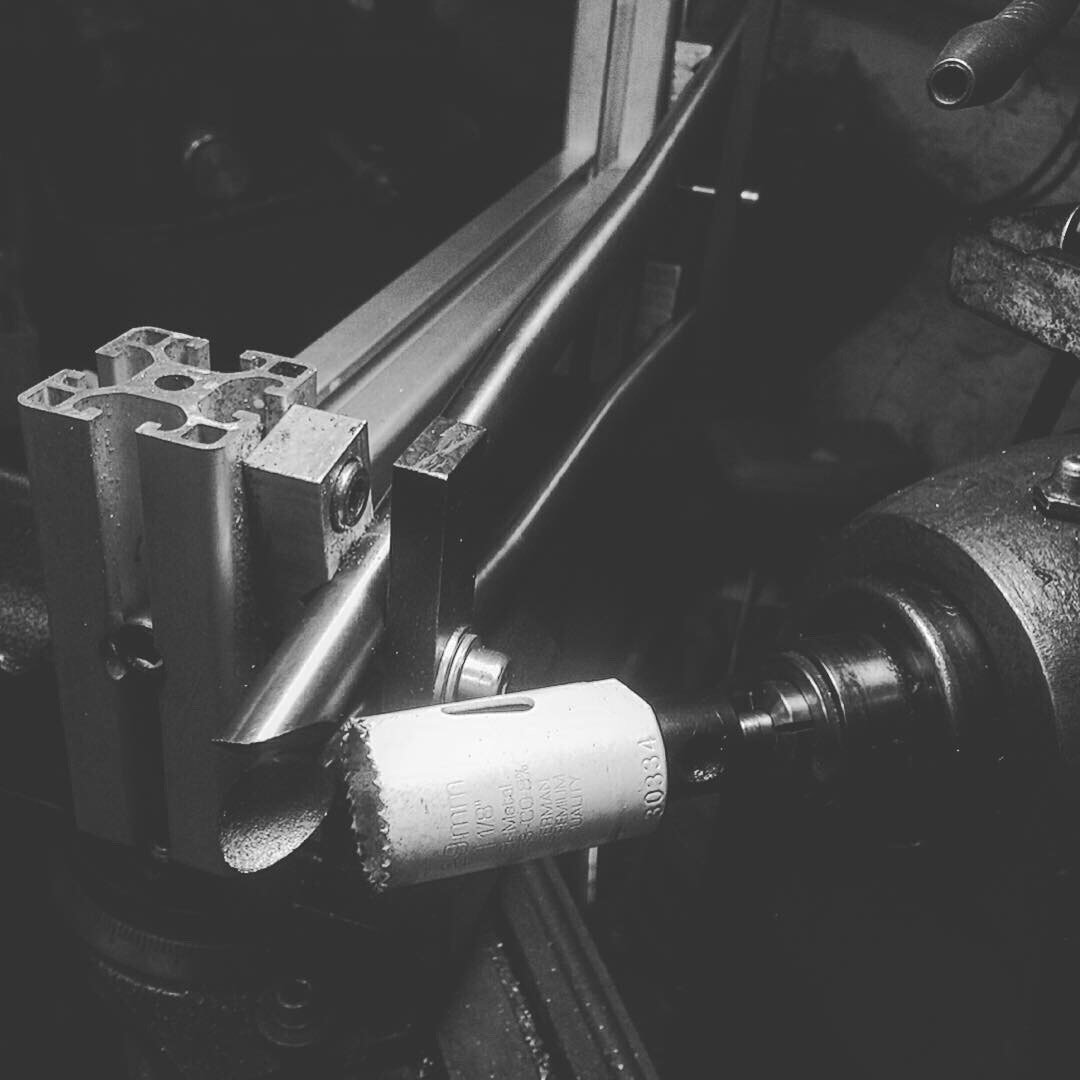

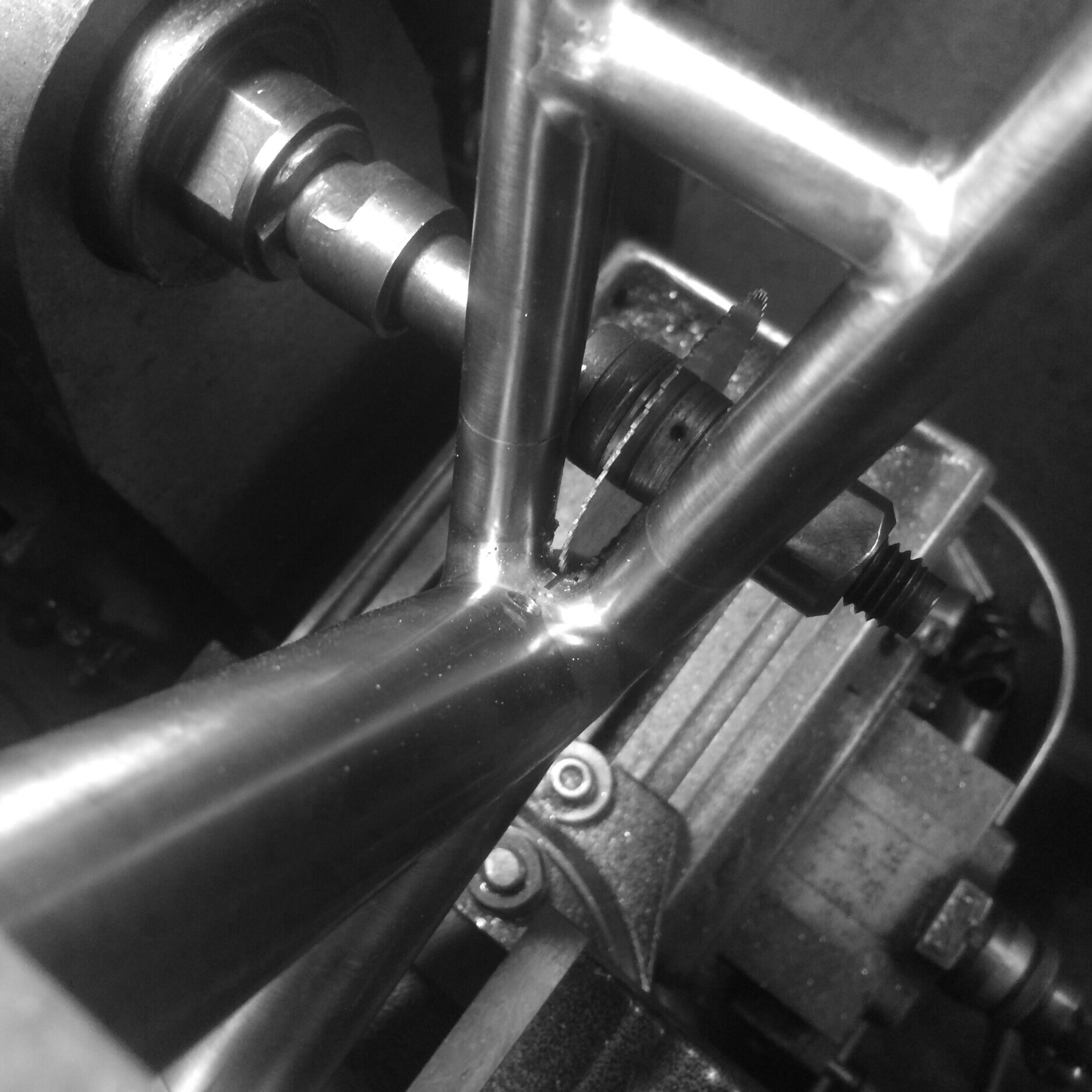

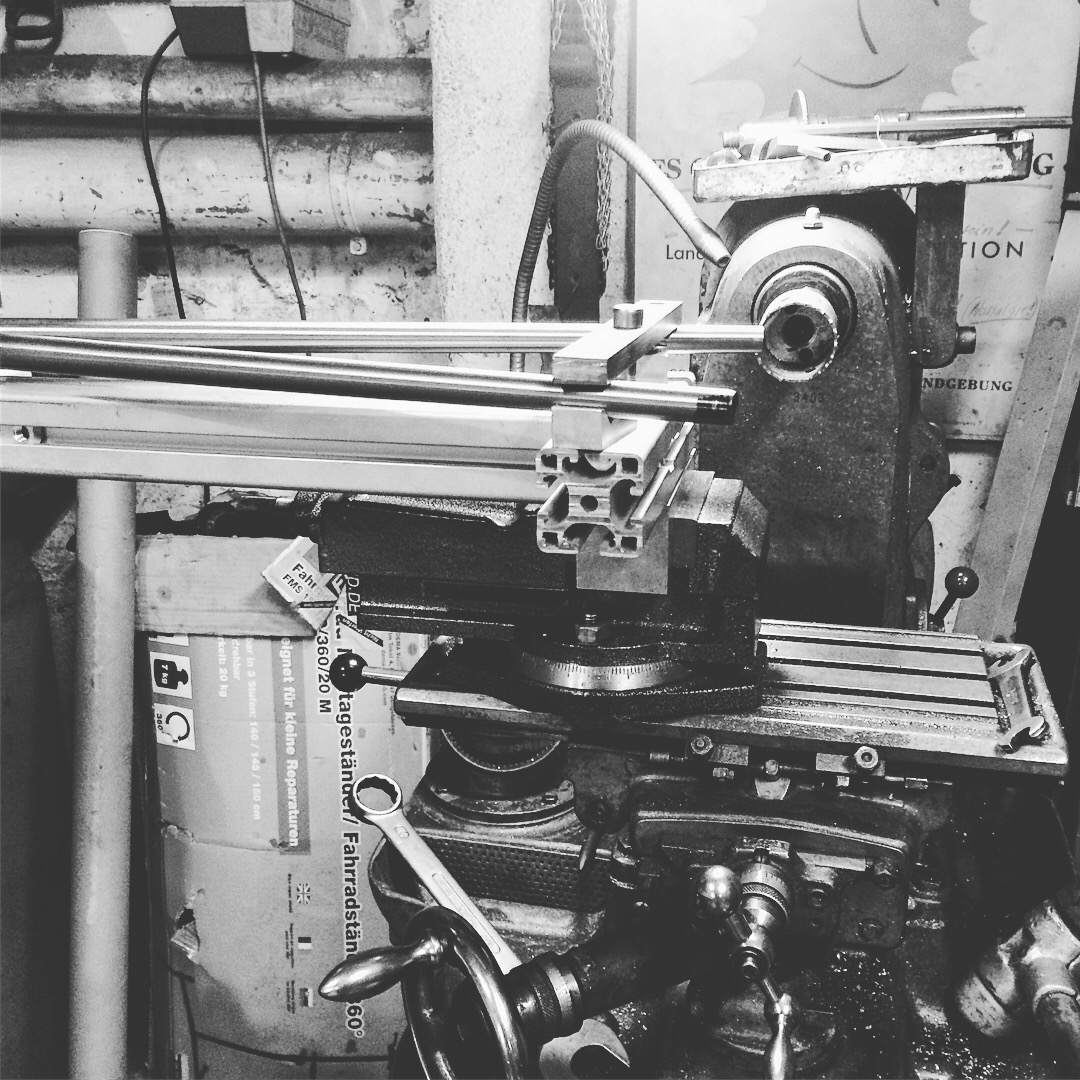

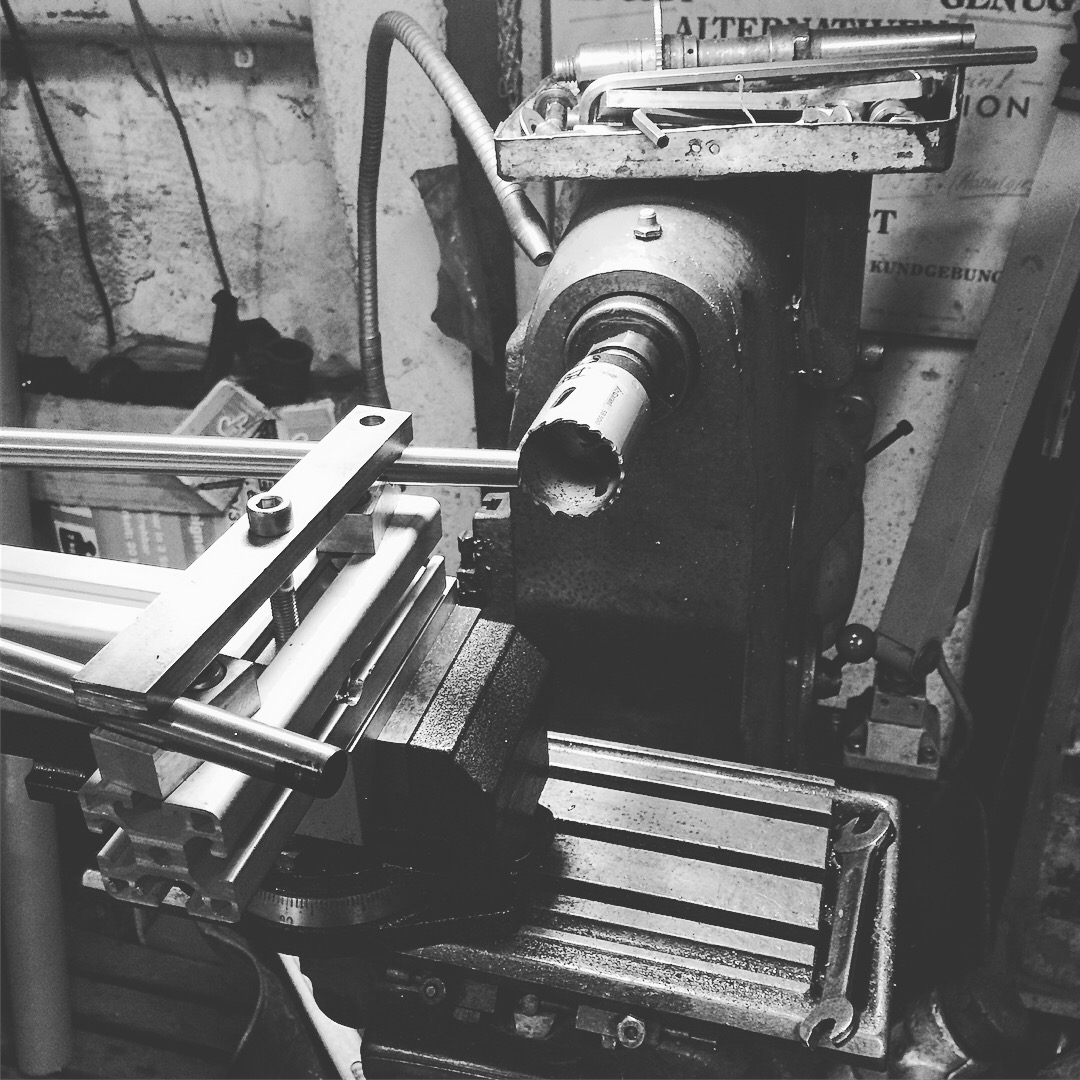

For the downtube we choosed a Megatube diamondshaped section. To get the right mitering to those section, the tubes are mitered in the specified angels on the the lathe machine.

The YAAD CYCLE-X Project is developed after the request to design a lugged Cyclecross-machine. The goal was to create a frame with a high amount of technical devices and give it a very simple and clean look. This demanded for integrated cable routing in the tubes and so every cable is routed directly to its device.

The dropouts are manufactured in stainless steel from paragonmachineworks. And to give enough room for cross-tires and the disk-brakes the frameend is designed with S-bend shaped tubing.

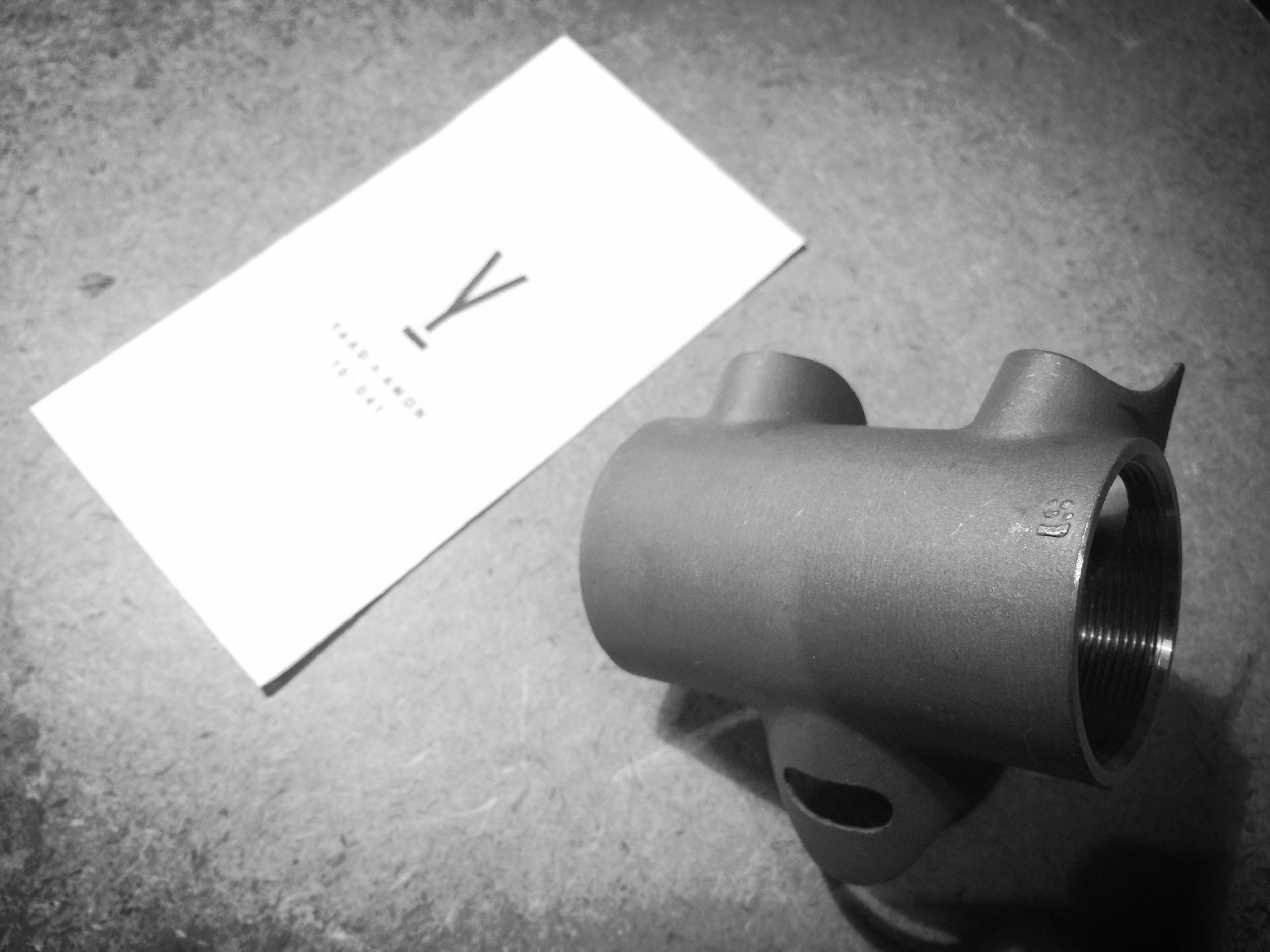

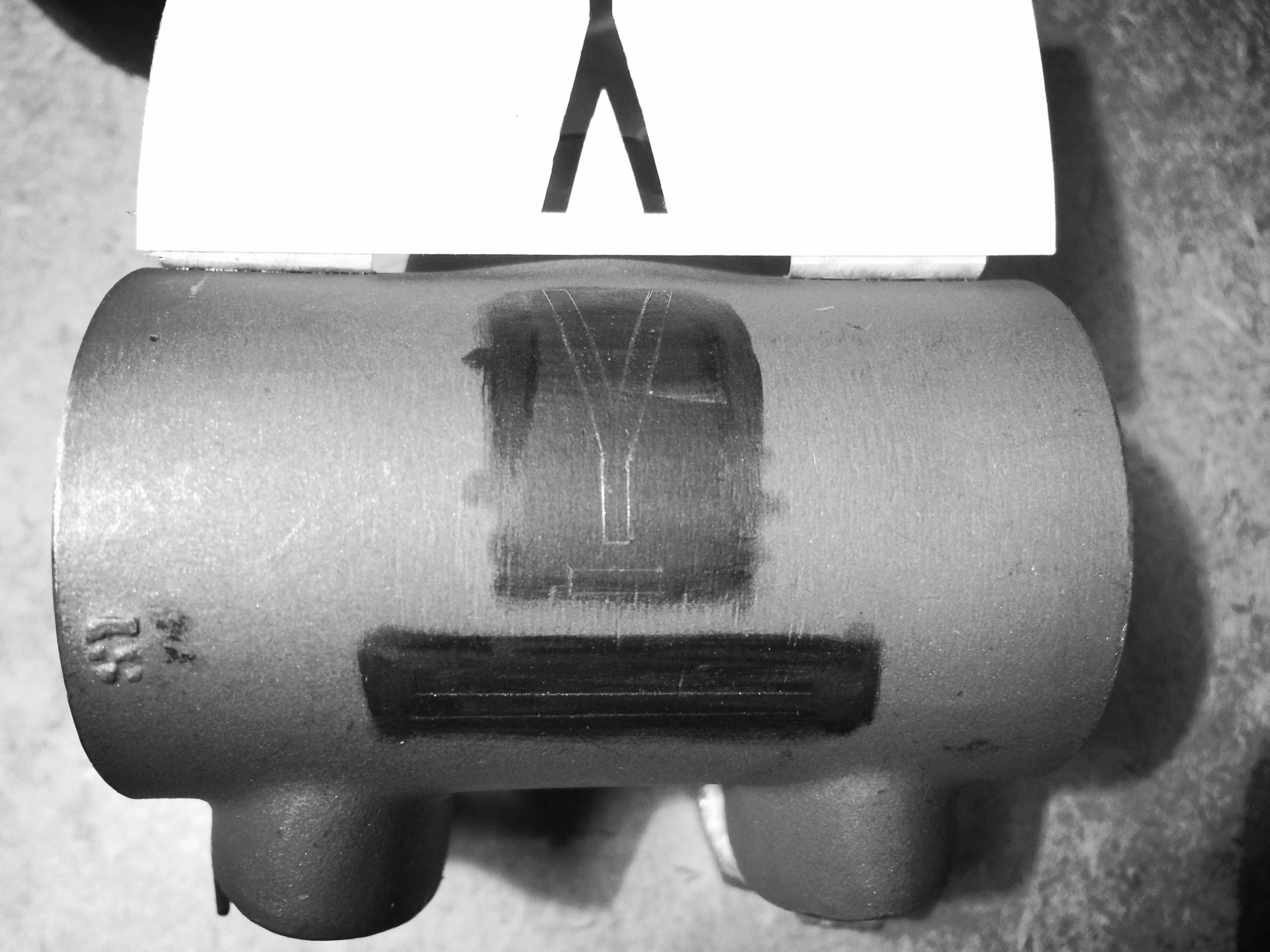

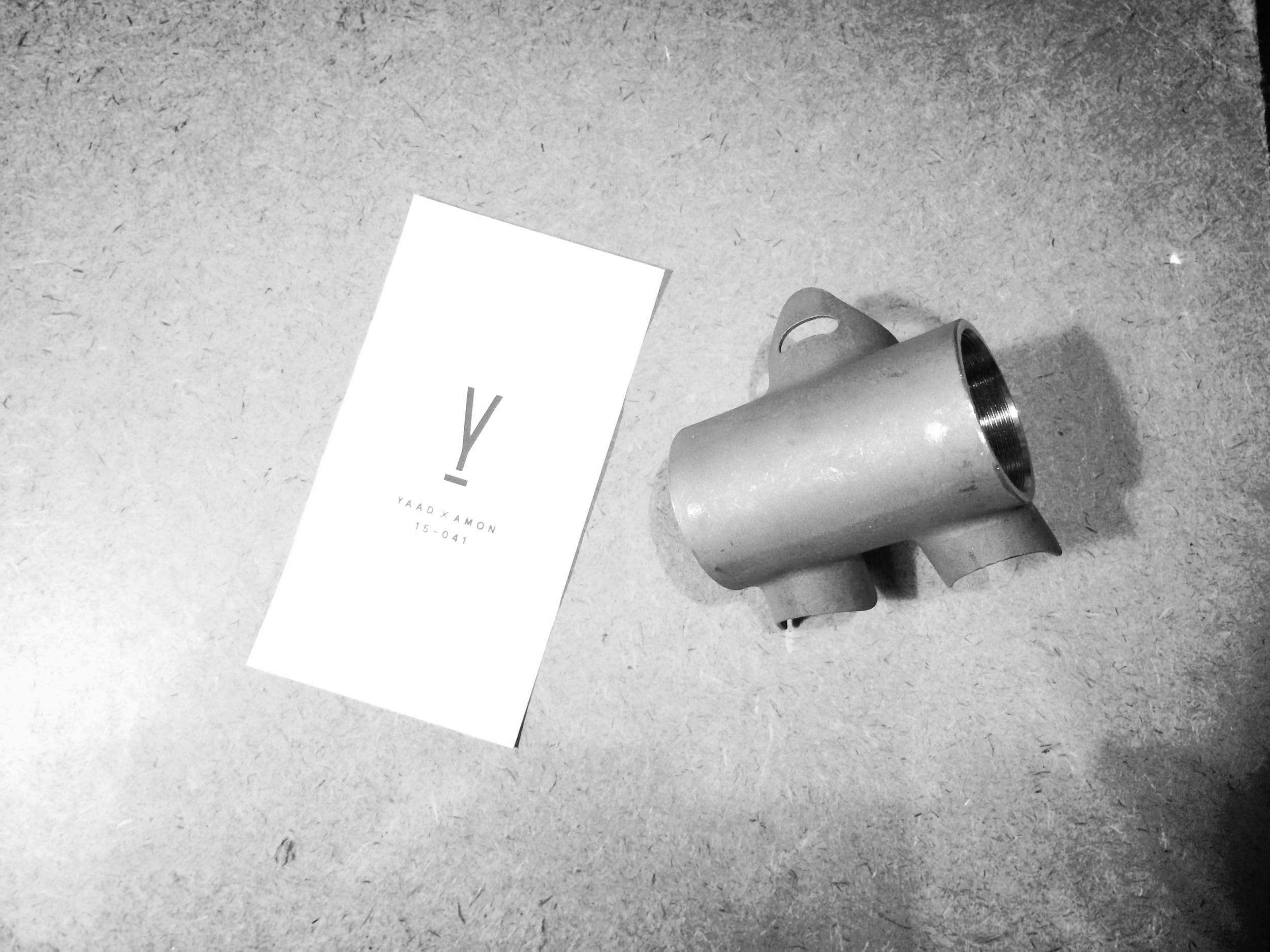

The AMON X YAAD Project is a cooperation with the Clothing brand AMONCLOTHING out of Hamburg. The aim was to translate their delicate, minimalistic and detailed design approach in the build of a very unique bicycle.

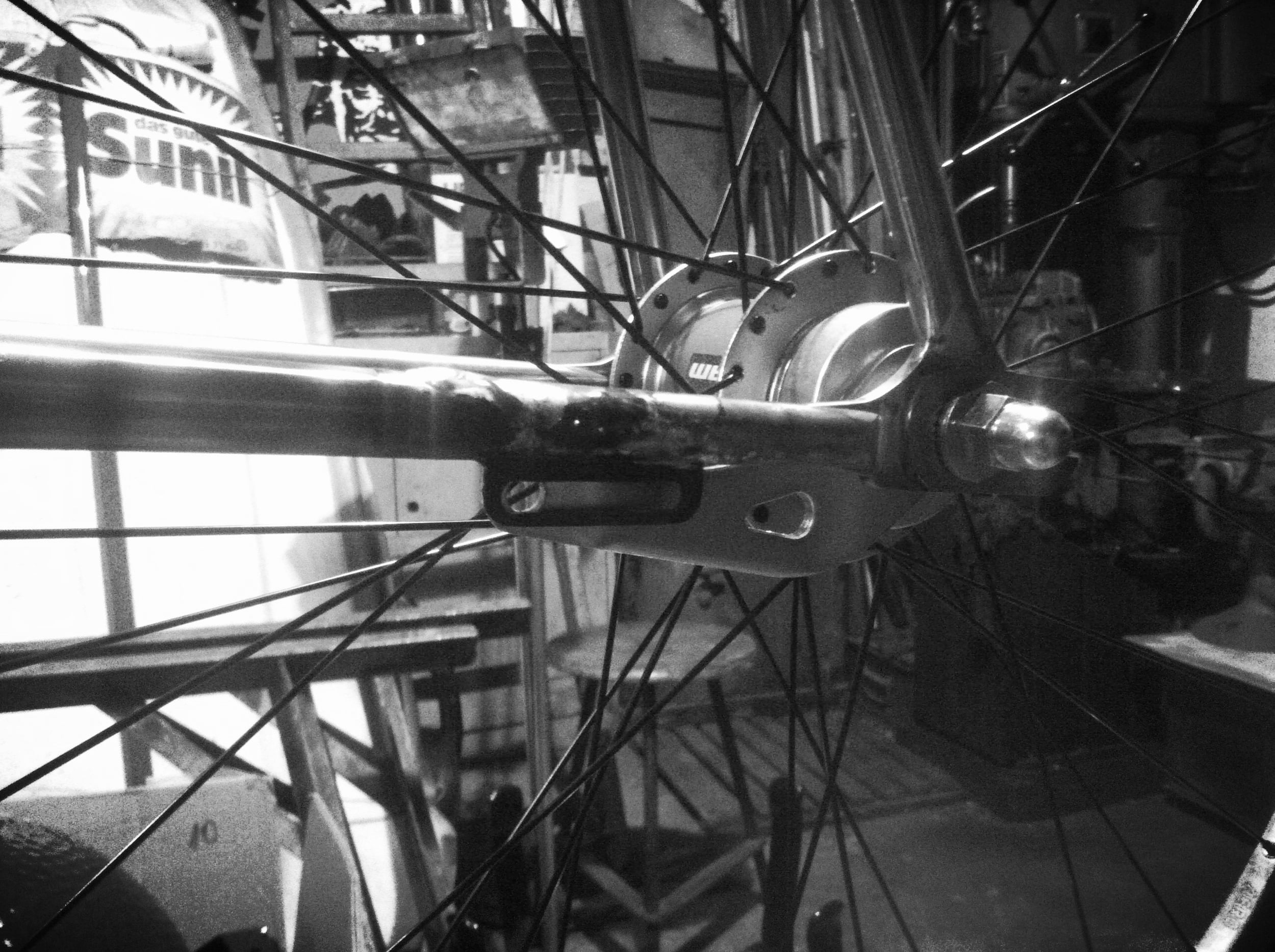

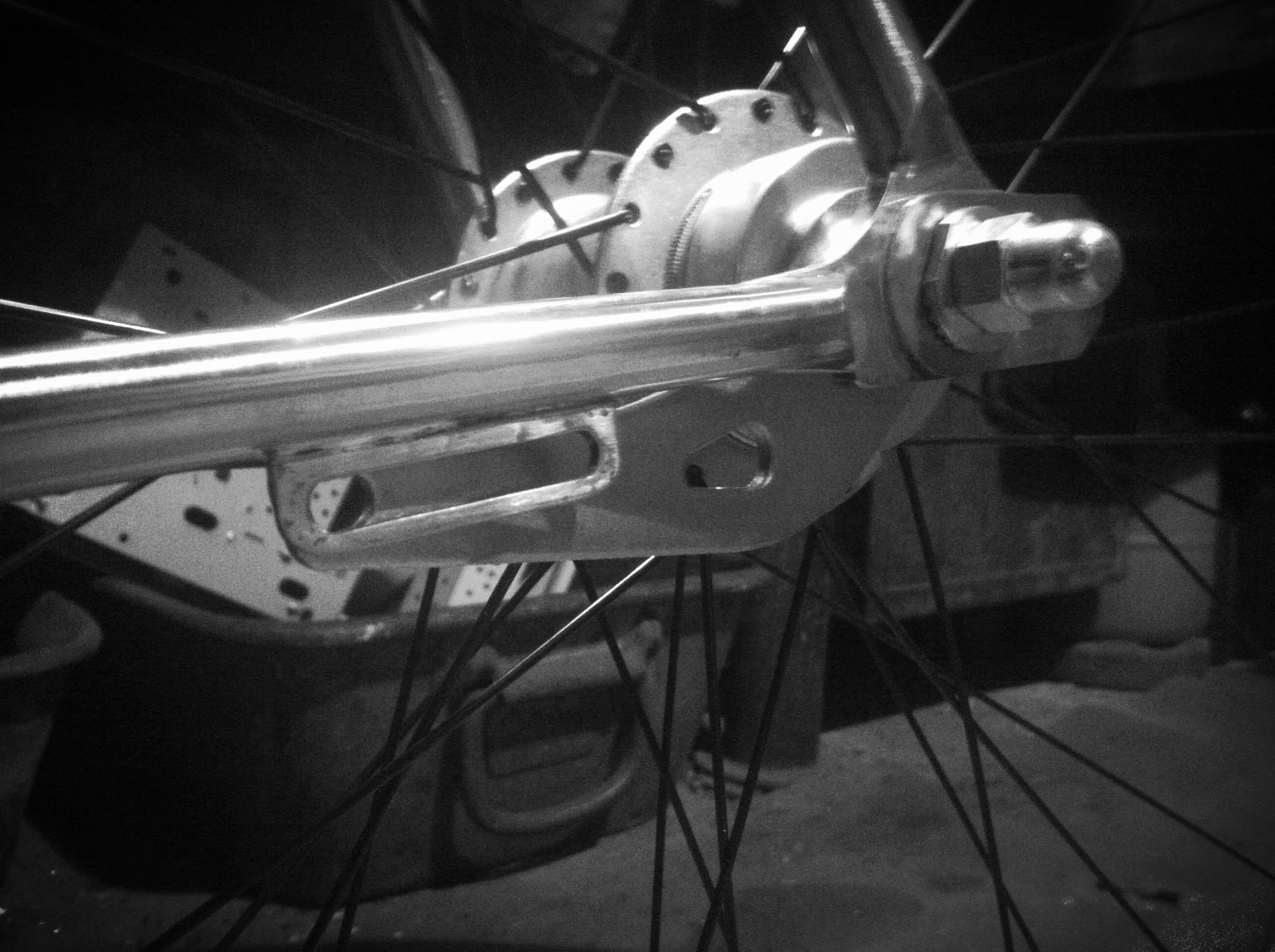

The choice was a Trackbike-design which is dedicated to some very fine details as for example the handcrafted rear dropouts, the embossed logo designs on the BB and the dropouts, the integrated Fast-Back-Raleigh Seatpost clamping.

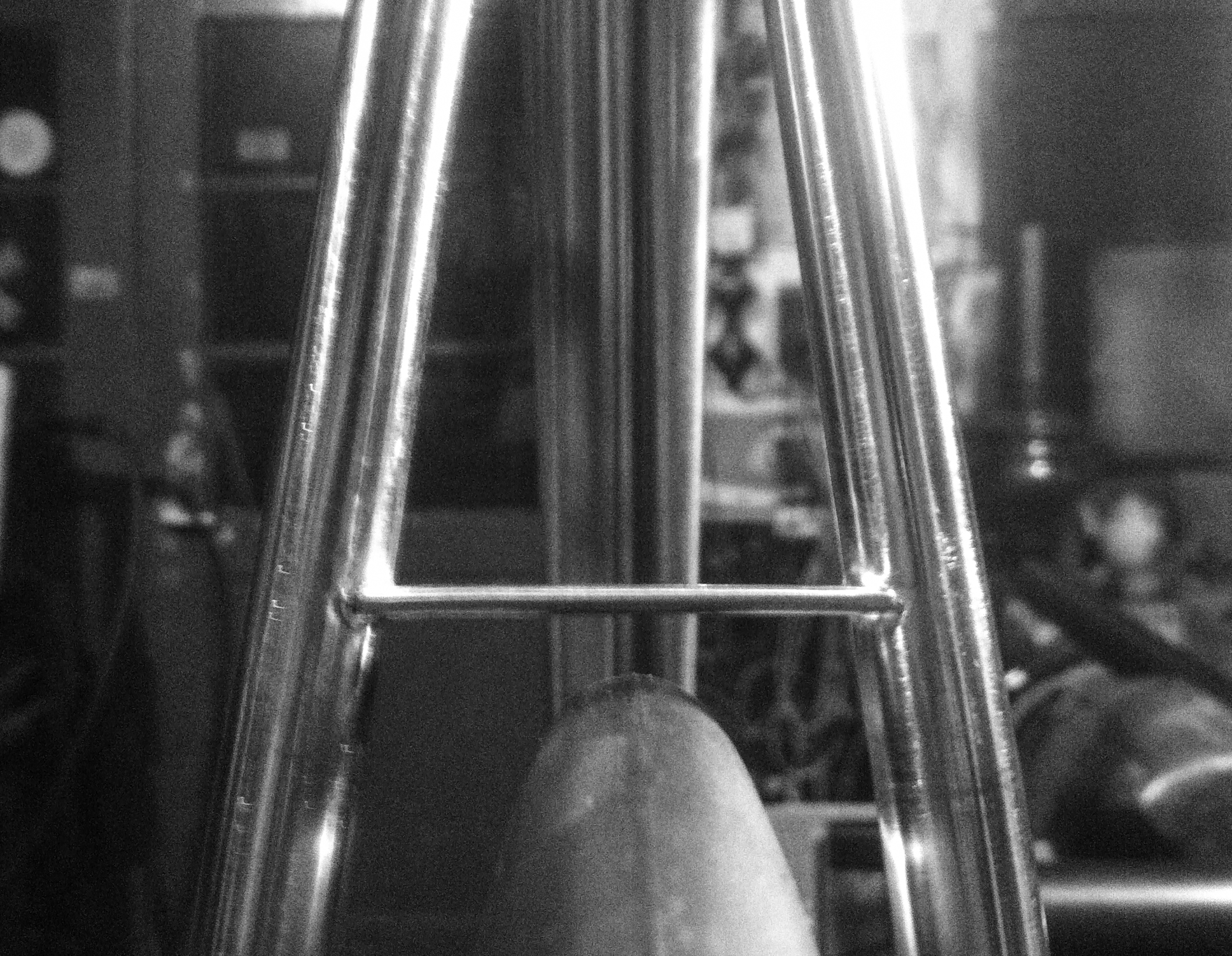

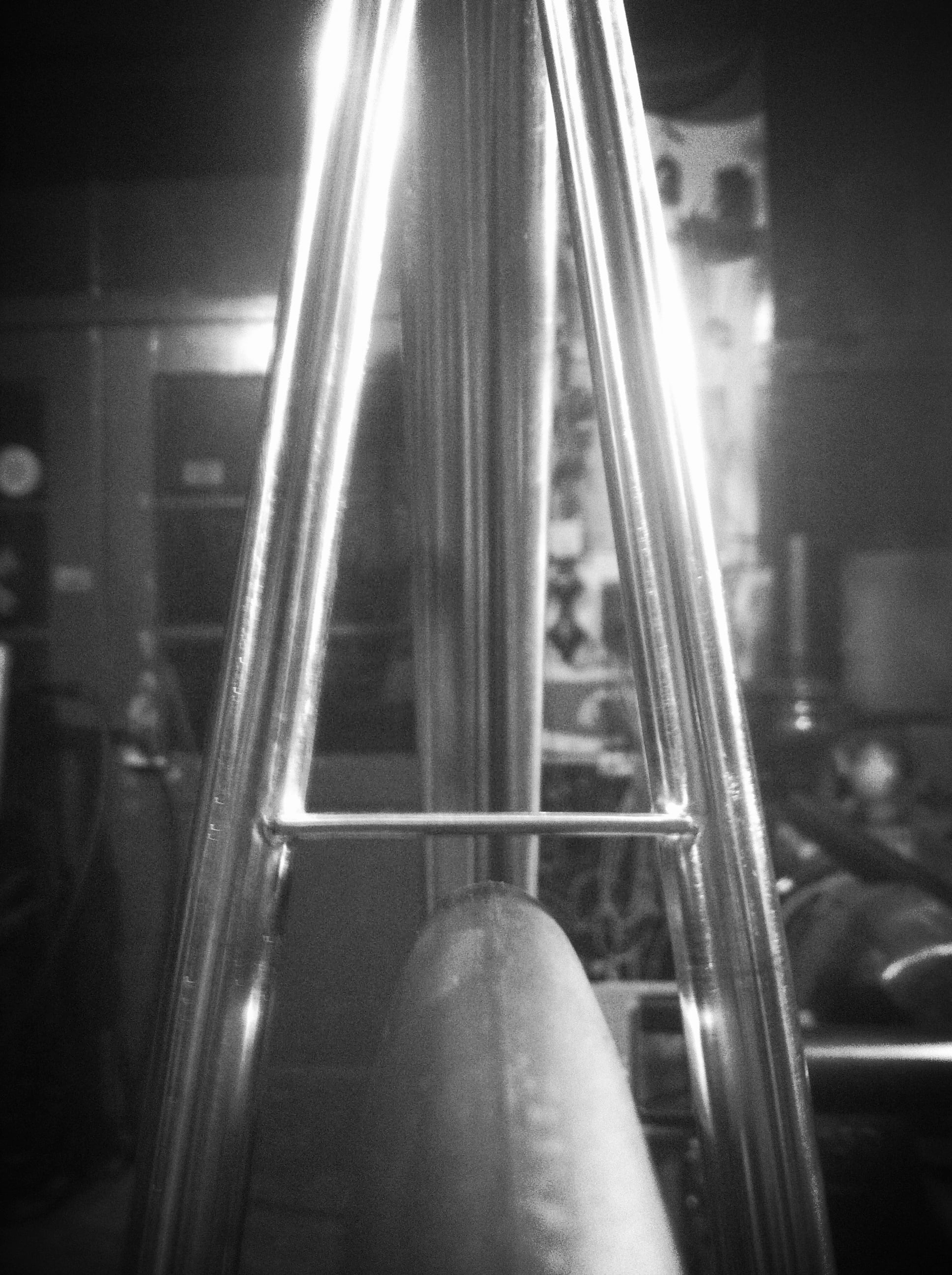

The goal was to develop a Track-design with hidden details which gives you the ability to use the bike daily in the streets. The frame is made from Columbus tubing brazed in LongShen Lugs. Some nice details are included like the integrated chainstay-bridge in the BB-shell

and the brake-bridge design is done with three thin rods dedicated to one of the MASTERS. And the track-dropouts are handmade to support a SRAM AUTOMATIX Hub which will give the bike its fluid drive with integrated coaster braking.

AND FOR MORE VISIT US ON

SHOP LOCATION

Hagelschieß 5

PO 70372 Stuttgart

Germany